Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Automatically Detect the LPG Gas Level and to Prevent the Gas Leakage and Accident Using Embedded System

Authors: Sundar G., K. Anupriya, T. Balasubbulakshmi

DOI Link: https://doi.org/10.22214/ijraset.2024.63858

Certificate: View Certificate

Abstract

This abstract introduces an IoT-based system designed to monitor liquefied petroleum gas (LPG) levels, detect leakages, and prevent accidents using Arduino. The system comprises several key components, including a load cell for accurate gas level measurement, an MQ2 gas sensor for leakage detection, and a fire sensor for hazard identification. Integrated relays control essential actuators such as an exhaust fan for ventilation, emergency lights for visibility enhancement, and a water pump for fire suppression. The GPS are used are track the location when accident occurs, the GPS will send the Latitude and Longitude of the accident location to the Rescue team. The load cell are used to notify the weight of the LPG Gas, when the LPG Gas going to empty the notification is send using the blink app. The Gas are automatically Booked using the IOT. Through the convergence of IoT and Arduino technology, this system aims to elevate safety standards in LPG-utilizing environments, offering proactive interventions to mitigate risks and safeguard lives and properties. The subsequent sections will delve into the components, operation, and benefits of the proposed system, elucidating its potential to transform LPG safety paradigms and foster a culture of secure energy usage

Introduction

I. INTRODUCTION

In modern society, liquefied petroleum gas (LPG) stands as a vital energy source, extensively used in households, businesses, and industries worldwide.

Its convenience, affordability, and versatility make it indispensable for cooking, heating, and various industrial processes. However, the inherent flammability and potential hazards associated with LPG demand stringent safety measures to prevent accidents and ensure secure usage.

The safe handling and management of LPG necessitate continuous monitoring of gas levels, timely detection of leakages, and swift response to any potential threats.

Traditional methods often fall short in providing real-time insights and proactive interventions, leaving room for accidents and endangering lives and properties. In response to this need, the integration of Internet of Things (IoT) technology and microcontroller platforms such as Arduino presents a promising avenue for enhancing LPG safety protocols.

By leveraging IoT's connectivity and data processing capabilities alongside Arduino's versatility and ease of programming, innovative systems can be developed to monitor LPG usage comprehensively, detect anomalies promptly, and implement preventive measures swiftly.

This paper introduces an IoT-based system designed to revolutionize LPG safety through real-time monitoring, leakage detection, and accident prevention.

The system integrates various sensors, including gas sensors for leakage detection and fire sensors for hazard identification, with actuators such as exhaust fans and water pumps for prompt response to emergencies . The Arduino microcontroller serves as the central processing unit, orchestrating data collection, analysis, and control functions seamlessly.

II. COMPONENTS AND WORKING

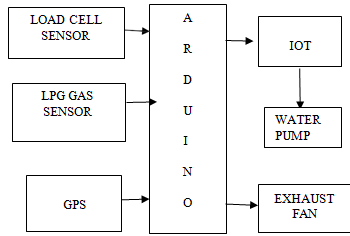

A. Block Diagram

Figure 1 Block Diagram

In Fig 1. The Block diagram 4.2.1 shown that the Load cell, Gas sensor, the fires sensor and GPS are connected to the Arduino. The Power supply are given 12V the regulator are used to convert the 12 v to 5v supply .The Load cell are used to known the Gas level , the fire sensor are used to Indicate the fire, Gas sensor are used to senses the Gas Leakage. The information from the sensor is given to Arduino. The output from the Arduino is connected to Three Relay. When the Fire detected the relay connected with water pump will automatically on. When the Gas sensor is detected the Gas leakage the relay connected to the Exhaust Fan will Run and the Light will automatically off. When The Fire sensor are sensed and accident occur GPS are used to send the Latitude and Longitude of the location to the rescue team.

III. METHODOLOGY

A. Load Cell Sensor

The strain gauges are wired as a Wheatstone-bridge to compensate for temperature changes. When the system is not loaded all four resistors are the same and the input of the amplifier is zero. When an object is placed on the pan R1 and R4 are compressed and their resistance decreases, R2 and R3 are strained and their resistance is increased. This causes a voltage difference at the input of the amplifier, proportional to the weight of the object. The shape if this spring body is comparable with the basic construction of the electronic balance with two guides.The strain-gauge method of measurement has its limitations for high resolution weighing machines, which are primarily due to creep in the spring material and the adhesive between the spring body and the strain gauges. The moisture sensitivity of the adhesive and the low output signal also cause difficulties. The major advantages of this method are the compact design,cost and its easy adaptability to various maximum capacities.

B. Node MCU

Node MCU is an open source IoTplatform. It includes firmware which runs on the ESP8266 WiFi SoC from Espress if Systems, and hardware which is based on the ESP-12 module. The term "Node MCU" by default refers to the firmware rather than the development kits. The firmware uses the Lua scripting language. It is based on the eLua project, and built on the Espress if Non-OS SDK for ESP8266. It uses many open source projects, As Arduino.cc began developing new MCU boards based on non-AVR processors like the ARM/SAM MCU and used in the Arduino Due, they needed to modify the Arduino IDE so that it would be relatively easy to change the IDE to support alternate tool chains to allow Arduino C/C++ to be compiled for these new processors. They did this with the introduction of the Board Manager and the SAM Core. A "core" is the collection of software components required by the Board Manager and the Arduino IDE to compile an Arduino C/C++ source file for the target MCU's machine language. Some ESP8266 enthusiasts developed an Arduino core for the ESP8266 WiFiSoC, popularly called the "ESP8266 Core for the Arduino IDE". This has become a leading software development platform for the various ESP8266-based modules and development boards, including Node MCUs.

C. Arduino UNO

The Arduino Uno is a microcontroller board based on the ATmega328. It has 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16 MHz crystal oscillator, a USB connection, a power jack, an ICSP header, and a reset button.

It contains everything needed to support the microcontroller; simply connect it to a computer with a USB cable or power it with a AC-to-DC adapter or battery to get started. The Uno differs from all preceding boards in that it does not use the FTDI USB-to-serial driver chip. Instead, it features the Atmega8U2 programmed as a USB-to-serial converter. "Uno" means one in Italian and is named to mark the upcoming release of Arduino 1.0. The Uno and version 1.0 will be the reference versions of Arduino, moving forward.

The Uno is the latest in a series of USB Arduino boards, and the reference model for the Arduino platform; for a comparison with previous versions. Arduino’s processor basically uses the Harvard architecture where the program code and program data have separate memory. It consists of two memories- Program memory and the data memory.The code is stored in the flash program memory, whereas the data is stored in the data memory. The Atmega328 has 32 KB of flash memory for storing code (of which 0.5 KB is used for the bootloader), 2 KB of SRAM and 1 KB of EEPROM and operates with a clock speed of 16MHz.

D. Buzzer

A buzzer or beeper is a signalling device, usually electronic, typically used in automobiles, household appliances such as a microwave oven, or game shows. It most commonly consists of a number of switches or sensors connected to a control unit that determines if and which button was pushed or a preset time has lapsed, and usually illuminates a light on the appropriate button or control panel, and sounds a warning in the form of a continuous or intermittent buzzing or beeping sound. Initially this device was based on an electromechanical system which was identical to an electric bell without the metal gong (which makes the ringing noise).

E. LPG Gas Sensor

Ideal sensor for use to detect the presence of a dangerous LPG leak in your car or in a service station, storage tank environment. This unit can be easily incorporated into an alarm unit, to sound an alarm or give a visual indication of the LPG concentration. The sensor has excellent sensitivity combined with a quick response time. The sensor can also sense iso- butane, propane. The unit will work with a simple drive circuit and offers excellent stability with long life. This circuit is mainly designed to sense the present LPG GAS in the atmosphere. The LPG GAS (Propane) is sensed by the gas sensor. The gas sensor is the one type of transducer which produces the voltage signal depends on the gas level. Then the voltage signal is given to inverting input terminal of the comparator. The comparator is constructed by the operational amplifier LM 741. The reference voltage is given to non inverting inputterminal. The comparator compares with normal reference signal and produces the corresponding output error signal. Then the output voltage is given to microcontroller in order to determine the presence of a dangerous LPG leak.

F. Global Positioning System(GPS)

The Global Positioning System (GPS), that provides geolocation and time information to a GPS receiver in all weather conditions, anywhere on or near the Earth where there is an unobstructed line of sight to four or more GPS satellites. The GPS system operates independently of any telephonic or internet reception, though these technologies can enhance the usefulness of the GPS positioning information. The GPS system provides critical positioning capabilities to military, civil, and commercial users around the world.

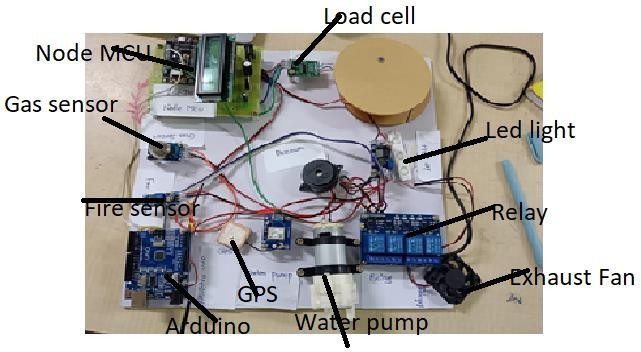

IV. HARDWARE AND RESULT

Figure 2 Hardware Model

The hardware model of the project is shown in Fig.2 , that the Arduino Uno has regulator which are used to convert the 12v to 5v supply to the devices. The fire sensor are connected to Arduino, when the fire are detect by fire sensor the buzzer will on and the water pump will automatically on. The Gas sensor are connected to Arduino, when the Gas leakage smell are detected the light will automatically on and exhaust Fan will run. Then the load cell are used to known the Gas level when the Gas is low we get the notification Gas Low in the bylink App. Relay are used to connect the Exhaust fan, Water pump, Light and the Buzzer. The GPS are used when the fire occurs it will send the Latitude and Longitude location to the rescue team. The notification are send to the rescue team using the bylink app.

Figure 3:Result

Figure 3 shows GPS Location are used to send the Latitude and Longitude of the LPG Gas accident detected Location to the rescue team. The Notification send to recuse team using bylnk app. The Bylink app is an IOT Wifi module of the System.

Conclusion

In conclusion, an IoT approach for gas leakage detection system at a low concentration is described. The leakage is detected using the MQ-6 gas sensor. The sensor sends a signal to ESP2866 Node MCU microcontroller. In the next step, microcontroller sends an active signal to other externally connected device which performs a cell phone. The efficiency of the Node MCU is proven through sending multiple messages to the Telegram application that could be a message per second, which is faster than other IoT platforms. This easy control over the devices like exhaust fan makes the environment less accident- prone. Using the Node MCU microcontroller also makes the system cheaper. Quick access and control make the system very useful. In addition, this paper presents a gas leakage detection system using IoT platforms; Telegram application to alarm the regarding person and send message to the user and alerting the user through buzzer. When the accident occur the GPS will send the Location to the rescue team the current Latitude and longitude location.

References

[1] Kumar Keshamoni, Sabbani Hemanth, “Smart Gas Level Monitoring, Booking and Gas Leakage Detector over IoT”, IEEE 7th International Advance Computing Conference,2017. [2] Chaitali Bagwe, Vidya Ghadi, Vinayshri Naik, Neha Kunte, “IOT Based Gas Leakage Detection System with Database Logging, Prediction and Smart Alerting- Review”,March 2018. [3] B. D. Jolhe, P. A. Potdukhe, N. S. Gawai, “Automatic LPG Booking, Leakage Detection And Real Time Gas Measurement Monitoring System”, International Journal of Engineering Research & Technology (IJERT) ,April 4, 2013. [4] R.Naresh Naik, P.Siva Nagendra Reddy, S.Nanda Kishore, K.Tharun Kumar Reddy. “Arduino Based LPG gas Monitoring & Automatic Cylinder booking with Alert System”, IOSR Journal of Electronics and Communication Engineering (IOSR- JECE), August 2016. [5] S.Rajitha, T.SWAPNA, “A Security Alert System Using Gsm For Gas Leakage”, International Journal Of VLSI And Embedded Systems,2012. [6] Shruthi Unnikrishnan, Mohammed Razil, Joshua Benny, Shelvin Varghese and C.V. Hari,“LPG Monitoring and Leakage Detection System”, IEEE WiSPNET, 2017 [7] Arun Raj, Athira Viswanathan, “LPG gas monitoring system”, INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH, Volume No.3, 2015. [8] Https://Www.Projectsof8051.Com/Iot-lpg-leakage- detector-project/ [9] Https://Www.Projectsof8051.Com/Gsm-based-lpg-weight- and-lpg-leakage-detection- system/ [10] Https://Www.Survivingwithandroid.Com/2017/02/Build- iot-project-arduino-sensor- 3-steps.Html [11] https://www.engineersgarage.com/insight/how-gas- sensor-works [12] https://instrumentationtools.com/load-cell-working- principle [13] https://www.electronicwings.com/nodemcu/nodemcu- gpio-with-arduino-ide

Copyright

Copyright © 2024 Sundar G., K. Anupriya, T. Balasubbulakshmi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63858

Publish Date : 2024-08-01

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online